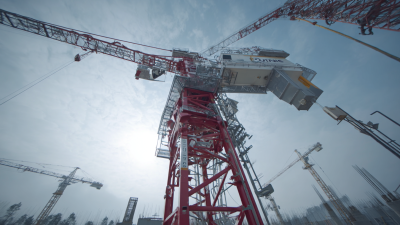

When considering the performance of a Dahan Used Tower Crane, it's essential to have a comprehensive evaluation checklist to ensure you're making informed decisions. Tower cranes are pivotal in construction projects, offering unmatched lifting capabilities and efficiency. However, with various models and conditions on the market, assessing a used crane's functionality and suitability can be daunting. This ultimate checklist will guide you through critical factors such as load capacity, lifting height, maintenance history, and operational efficiency, thereby enabling you to maximize your investment and enhance project productivity. Whether you're a contractor, project manager, or construction business owner, understanding how to effectively evaluate a Dahan Used Tower Crane can be the key to achieving success in your construction ventures.

When assessing the efficiency of Dahan used tower cranes, key performance indicators (KPIs) play a pivotal role. These indicators help evaluate various aspects of a crane's working capabilities, including load capacity, operational speed, and mechanical reliability. Tracking these metrics can provide insights into the crane's performance over time, enabling more informed decisions regarding maintenance and usage. Moreover, monitoring these KPIs aids in benchmarking against industry standards, ensuring that the equipment operates within optimal parameters.

As the tower crane rental market is projected to soar to USD 22.1 billion by 2030, understanding the performance indicators becomes even more critical. With the growing demand for efficient and robust cranes driven by construction and infrastructure development, it’s essential for businesses to focus on KPIs that reflect not only current operational efficiencies but also potential growth areas. Effective evaluation of these indicators not only enhances productivity but also ensures safety and compliance with industry regulations, ultimately contributing to business expansion in a competitive marketplace.

When evaluating the performance of Dahan used tower cranes, understanding the impact of load capacity is crucial. Load capacity directly influences how the crane functions under various operational conditions. A crane with a higher load capacity can handle heavier loads with greater efficiency, but this does not necessarily translate to better overall performance. Factors such as lifting speed, stability, and the ability to maneuver in tight spaces can also be affected by the crane’s maximum load capacity. Therefore, when assessing a Dahan crane, it’s essential to consider how the load capacity integrates with these performance metrics.

Additionally, the operational environment plays a vital role in how load capacity affects performance. For instance, a tower crane working on a construction site with limited vertical space may struggle despite its high load capacity if it cannot navigate effectively. Furthermore, oversized loads can strain the crane’s mechanics, reducing its lifespan and increasing maintenance costs. Thus, when evaluating the Dahan used tower crane, professionals must ensure that the load capacity is balanced with the demands of the specific job site, ensuring both safety and efficiency in operations.

This chart illustrates the effect of varying load capacities on the performance metrics of tower cranes. The load capacities are categorized into three levels: Low (1-5 tons), Medium (6-10 tons), and High (11-15 tons). The performance metrics measured include Lift Speed, Stability, and Maintenance Needs, all of which indicate how effectively the crane operates under different load conditions.

When evaluating the performance of Dahan used tower cranes, one of the critical factors to consider is their operational hours. The lifespan of a tower crane is significantly impacted by the hours it has been in use, as this metric provides insights into the machine's wear and tear. Typically, Dahan cranes are designed for robust performance, but understanding the correlation between operational hours and maintenance needs can guide users in making informed purchasing decisions. Experts often recommend assessing the regularity of usage—whether the crane was used intermittently on smaller projects or consistently on larger construction sites—since this can greatly influence its condition and longevity.

Additionally, examining the operational hours allows potential buyers to estimate the remaining useful life of the crane. A unit with lower hours may indicate less wear, but this must be balanced against the age of the crane and how it was maintained during its operational life. It's essential to review service records and any repairs performed, as these factors often reveal the actual condition of the crane beyond the numerical data. Ultimately, operational hours serve as a vital indicator in evaluating the overall performance and reliability of Dahan used tower cranes, ensuring that users can choose the best equipment for their construction needs.

Safety compliance standards for tower cranes are a critical focus in construction, especially with recent high-profile incidents raising concerns about operational risks. The BC Conservatives have highlighted the urgent need for improved crane safety recommendations from WorkSafeBC, noting that delays in publishing guidelines could lead to unnecessary hazards at construction sites. Such measures are not only essential for protecting workers but also for safeguarding the public and infrastructure from potential accidents.

As urban construction density increases, it becomes imperative to consider the various factors that impact crane safety, including environmental conditions such as high winds. Examples from cities like St. Petersburg emphasize that during extreme weather events, the integrity of tower cranes must be stringently monitored to prevent catastrophic failures. Efforts to incorporate AI and automation into crane operations could serve as a solution to enhance safety, ensuring that cranes are operated with precision and diminished risk. Implementing these advancements, paired with robust safety regulations, will elevate the standards of crane safety in the construction industry.

When it comes to enhancing the reliability and performance of Dahan used tower cranes, implementing robust maintenance practices is crucial. One of the key aspects of effective maintenance is the adoption of predictive maintenance strategies, which utilize real-time data to foresee potential issues before they escalate into costly breakdowns. By leveraging data analytics, crane operators can optimize maintenance schedules, ensuring that inspections and repairs are conducted at the most advantageous times.

Incorporating routine checks and adopting a systematic approach to maintenance not only prolongs the lifespan of the equipment but also minimizes downtime. Regular assessments of crucial components such as cables, hydraulic systems, and electronic controls can significantly reduce the risk of operational failures. Moreover, fostering a culture of continuous learning and improvement among maintenance personnel is essential. This involves providing training on the latest technologies and methodologies, empowering teams to make informed decisions that lead to enhanced crane performance and reliability.