Operating Tower Cranes requires precision and safety measures. Statistics from the International Organization of Construction Equipment suggest that improper crane operations contribute to about 40% of workplace accidents in the construction industry. In an environment where towering steel structures rise, the potential risks are ever-present.

Expert opinions highlight the necessity of adhering to safety protocols. John Smith, a leading specialist in crane operations, states, “Safety is not just a checklist; it’s a mindset.” His insight emphasizes that every operator must cultivate an awareness of their surroundings. Given the complexities of Tower Cranes, this mindset is vital for preventing accidents.

Moreover, training programs for crane operators often fall short of imparting essential skills. Many programs focus on theoretical knowledge but neglect real-world scenarios. Addressing this gap is critical to ensuring efficient and safe operations. The industry must continuously reflect on its training methods, striving to enhance safety practices for Tower Cranes and ultimately protect workers on-site.

Understanding the components of a tower crane is crucial for safe and efficient operations. The main parts include the mast, jib, counter-jib, and the operator’s cabin. Each component plays a specific role in lifting and positioning materials on construction sites. The mast provides the vertical support. The jib holds the load and extends outward, while the counter-jib balances the crane. The operator's cabin offers visibility and control.

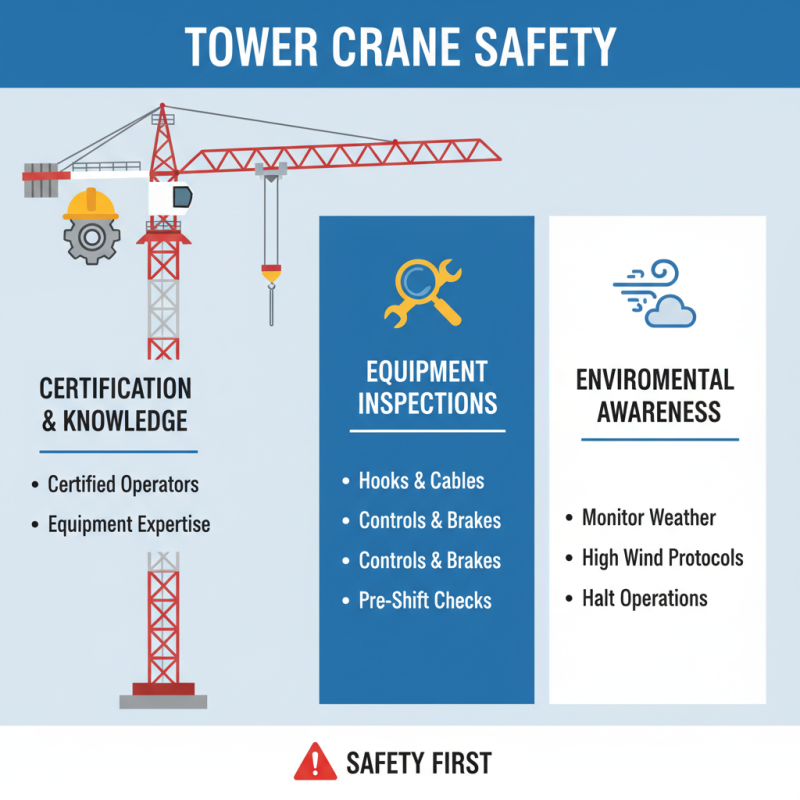

Remember to check the cranes before use. Inspect cables and hooks for signs of wear. Look for any loose connections on all parts. A simple inspection can prevent accidents. Always keep the immediately surrounding area clear. This ensures an unobstructed view for operators.

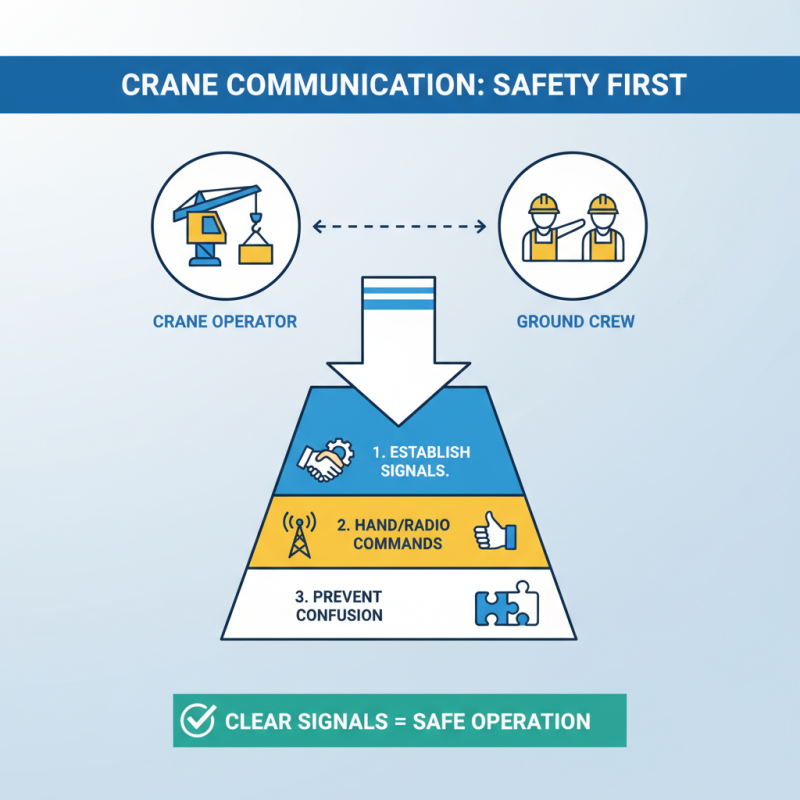

Regular training is also essential. It helps operators understand the function of each component better. Misunderstandings can lead to errors. Ensure that all team members know the crane's capabilities and limitations. Proper operation involves constant communication. A lack of clarity can result in unsafe practices. Establish signals or use radios to maintain clear dialogue at all times.

Assessing site conditions is crucial for the safe operation of tower cranes. Before setting up, a thorough site assessment must be performed. Look for overhead obstructions. Power lines, trees, and nearby buildings can pose serious risks. If they are too close, the crane's operation could be compromised.

Weather conditions also play a significant role. Wind can significantly impact crane stability. Check the local forecast before operation. High winds require immediate action. Operators must be alert and ready to halt work if conditions worsen. Regular communication with the crew is vital for safety.

Tip: Always inspect the ground conditions where the crane will be placed. Soft or uneven ground can lead to instability. A crane's base needs solid support. If the ground is questionable, consider additional measures like matting or leveling. Additionally, assessing the load weight and distribution is essential for safe lifting. A miscalculation can lead to tipping or accidents. These assessments may take time but are necessary for efficiency and safety.

Operating tower cranes involves several crucial safety protocols and regulations. Operators must be certified and understand the equipment deeply. Regular inspections of the crane are vital. Checkouts include assessing hooks, cables, and controls. Operators should also be aware of their surroundings. High winds can create hazards. It’s essential to halt operations when conditions worsen.

Proper communication is key to safety. Signaling between the operator and ground crew must be clear. Hand signals or radios can minimize accidents. A dedicated area should be established for crane operation. This keeps unauthorized personnel away. All team members must understand the plan. Briefings before shifts can help clarify roles. Miscommunication can lead to severe outcomes.

Climbing the crane for maintenance poses risks too. Safety harnesses are not optional; they are mandatory. Operators sometimes overlook minor details. Small errors can lead to serious incidents. Always keep safety first and foremost. Continuous training is necessary. Safety protocols are not just rules; they are essential for everyone’s well-being. Reflection on past mishaps helps improve practices.

Effective communication between crane operators and ground crew is crucial for safety. Clear signals must be established at the start of each project. Operators need to understand the ground crew's hand signals or radio commands. This clarity prevents confusion during operations. Simple gestures can convey important messages quickly.

Regular meetings can help improve communication. Discuss challenges faced in previous projects. Ground crew can express their concerns about visibility or equipment needs. These discussions bridge gaps in communication. However, not all teams take this time to connect. Without this effort, misunderstandings may arise.

Additionally, relying solely on technology can lead to issues. Overusing radios may create a false sense of security. Sometimes, operators misinterpret messages. Visual signals are often more reliable than verbal instructions. Ground crew should remain vigilant and proactive. They should always verify actions before proceeding. If there are doubts, pause and communicate.

Routine maintenance is key for tower crane efficiency. Regular inspections can prevent unexpected breakdowns. Check cables, pulleys, and gears weekly. Inspect the foundation and stability. Pay attention to any unusual noises. These signs could indicate deeper issues.

Lubrication is crucial. Use the right oils and greases to keep moving parts functioning smoothly. A well-lubricated crane operates better and lasts longer. Forgetting this step may lead to failures. Always take time to document each maintenance session for future reference.

Training operators on these practices is vital. They should understand the importance of daily checks. Encourage them to inspect the crane before it's used each day. This habit can catch problems early. Operators play a big role in safety and efficiency. When they are vigilant, everyone benefits.

| Maintenance Activity | Frequency | Purpose | Expected Outcome |

|---|---|---|---|

| Inspection of Hoisting Mechanism | Weekly | Ensure safe lifting operations | Prevent accidents and failures |

| Lubrication of Moving Parts | Monthly | Reduce friction and wear | Enhance crane performance |

| Electrical System Check | Quarterly | Identify electrical issues | Ensure operational safety |

| Structural Inspection | Semi-Annually | Check for wear and tear | Maintain structural integrity |

| Safety Equipment Testing | Annually | Verify functionality of safety devices | Ensure operator safety |