When considering the purchase of a Dahan Used Tower Crane, beginners often face uncertainty. The market is vast and varied. Understanding key aspects can simplify the process significantly.

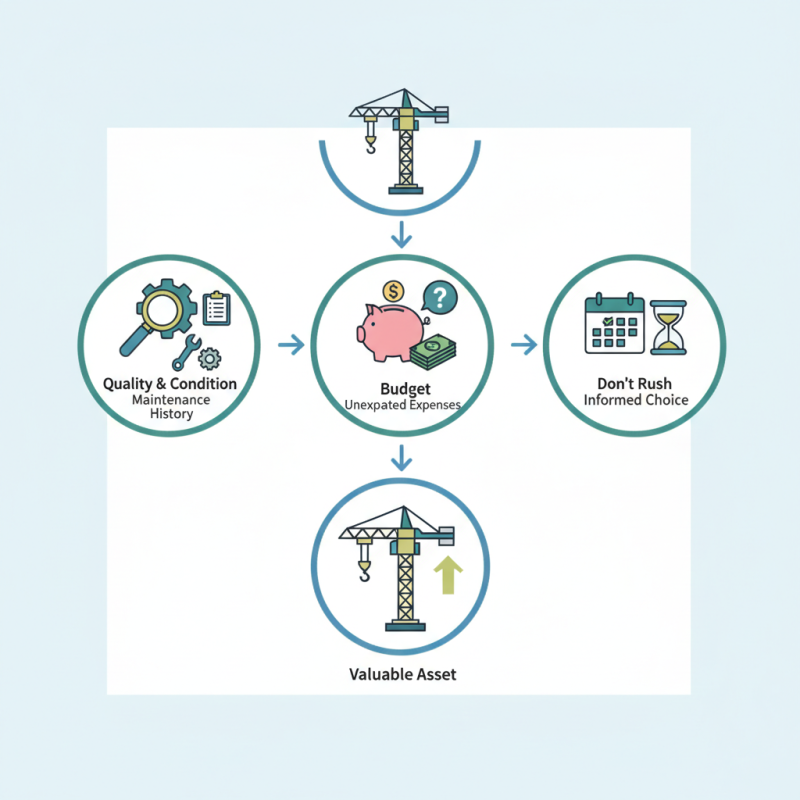

Quality and condition are vital. Inspecting the crane thoroughly ensures you avoid hidden issues. A Dahan Used Tower Crane may appear great but could hide significant wear and tear. Maintenance history is crucial; ask for records to gauge reliability.

Budget plays a critical role in any buying decision. Set a realistic budget considering both initial costs and potential repairs. Be prepared for unexpected expenses, which can complicate your investment. Balancing cost with quality is essential. Don't rush; take your time to make an informed choice. A well-chosen Dahan Used Tower Crane can be a valuable asset for years to come.

When considering a tower crane, several key features are essential. The lifting capacity is crucial. Understand the maximum weight the crane can handle. This affects what materials can be moved on your site. A crane that cannot lift your materials is a costly mistake.

Height and reach also matter significantly. Measure your construction site carefully. Ensure the crane can reach the highest points needed. A crane that is too short or lacks reach limits productivity. Check the boom length and the height under hook specifications.

Stability and safety features cannot be overlooked. Look for well-designed counterweights. Good stability ensures the crane remains in place during operations. Safety features such as overload alarms and limit switches are equally important. They protect your workers and materials. Be mindful that even with good features, cranes require regular maintenance to operate safely.

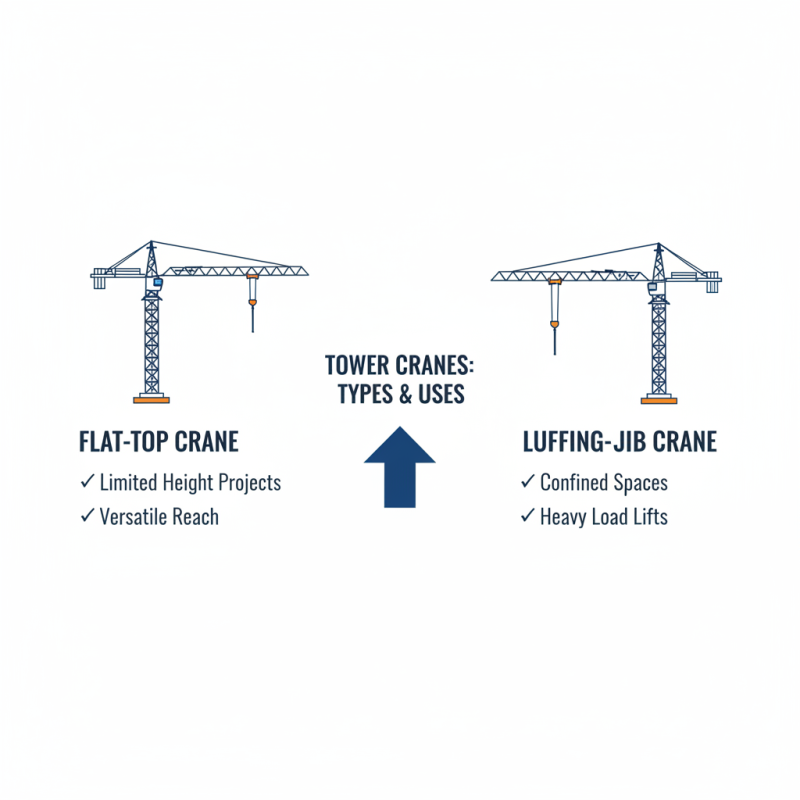

When exploring tower cranes, it's essential to understand their different types and specific applications. There are various tower cranes, each designed for unique tasks. The flat-top crane is well-suited for projects with limited height restrictions. It offers a versatile reach but requires careful assembly. Then, there’s the luffing-jib crane, known for its ability to work in confined spaces. It can lift heavy loads but comes with a complex setup that new users may find daunting.

Another popular type is the hammerhead crane. With its distinctive shape, it allows for greater lifting capacity. However, this crane needs considerable space for operation. Improper use can lead to safety concerns. Many beginners overlook the importance of understanding load capacities. Misjudging can lead to accidents or damage. It's crucial to take time to study and reflect on each crane type.

Maintenance is also a vital aspect. Tower cranes need regular inspections and maintenance to ensure peak performance. Many users fail to keep up with this, risking equipment reliability. Beginners should prioritize training and familiarize themselves with maintenance protocols. This knowledge is key to effectively operating and selecting the right crane for their projects.

When purchasing a tower crane, safety must be a top priority. Ensure that all components meet safety standards. You should check the crane's load capacity. Verify that it can handle your projects' demands. Inspect the manufacturer's certifications and maintenance history. Such due diligence can prevent accidents on site.

Choosing the right type of crane is critical too. Not all cranes fit every job. Consider the working environment. Is it urban with limited space? Or is it a vast construction site? Each scenario requires specific crane capabilities. It’s worth analyzing these factors carefully.

Remember to involve qualified professionals during your purchase process. Their expertise can provide insight that you might overlook. While you might think you can handle it alone, the complexities of cranes often require experienced judgment. Rushing decisions here can lead to costly errors. Safety should never be compromised for speed.

When budgeting for your first tower crane, it's essential to consider all costs involved. A new tower crane can range from $10,000 to $1,000,000. Prices depend on the model, capacity, and features. Used cranes may be cheaper, but they can hide hidden costs. These include repairs and maintenance. The average maintenance cost can be around $20,000 annually. Thus, don't ignore these ongoing expenses.

Financing options are vital for a smooth purchase. Many banks offer loans with rates around 6-8%. Some dealers also provide financing plans. However, interest can add significantly to the total cost, sometimes by 30% over the loan's lifetime. Depending on estimated cash flow, it’s wise to assess how much you can afford. Unexpected expenses can arise, so leave room in your budget.

Considering the market conditions is also important. According to industry reports, demand for tower cranes is expected to rise by 5% annually. This can affect resale values. Therefore, think about potential depreciation before buying. It’s a complex market. Research and planning are crucial for a successful investment.

When looking for a reliable supplier or manufacturer of tower cranes, experience matters.

Companies with a solid track record often provide better quality equipment. According to industry reports, nearly 70% of construction projects fail due to equipment issues. Therefore, selecting the right supplier is critical.

One key tip is to check certifications. Make sure the supplier complies with safety and quality standards. Quality certifications, such as ISO, can indicate a manufacturer's commitment to excellence. Investigating their past projects can offer insights into their reliability.

Communication is vital. Look for suppliers who respond quickly. Slow replies can signal a lack of professionalism. It’s important to engage with them early in the discussion.

Additionally, visiting the manufacturing site can reveal many things. If possible, observe their production process. It helps to see how they handle quality control. The condition of the site can be an indicator of their operational efficiency.

Finally, don't ignore customer testimonials. They often highlight strengths and weaknesses of the supplier. This feedback can guide your decision-making process. Engaging with previous clients can provide a clearer picture of what to expect.