Operating a Zoomlion Used Tower Crane effectively is crucial in construction projects. Expert engineer Jane Smith emphasizes, "Understanding the crane's capabilities can prevent accidents."

When using a Zoomlion Used Tower Crane, operators must prioritize safety and precision. Regular inspections are necessary, as wear and tear can affect performance. This machinery can be powerful but requires careful handling.

Operators should focus on their training and follow guidelines closely. Mistakes can lead to costly delays. For instance, misjudging load limits could result in a dangerous situation. Reflection on past experiences will enhance future performance.

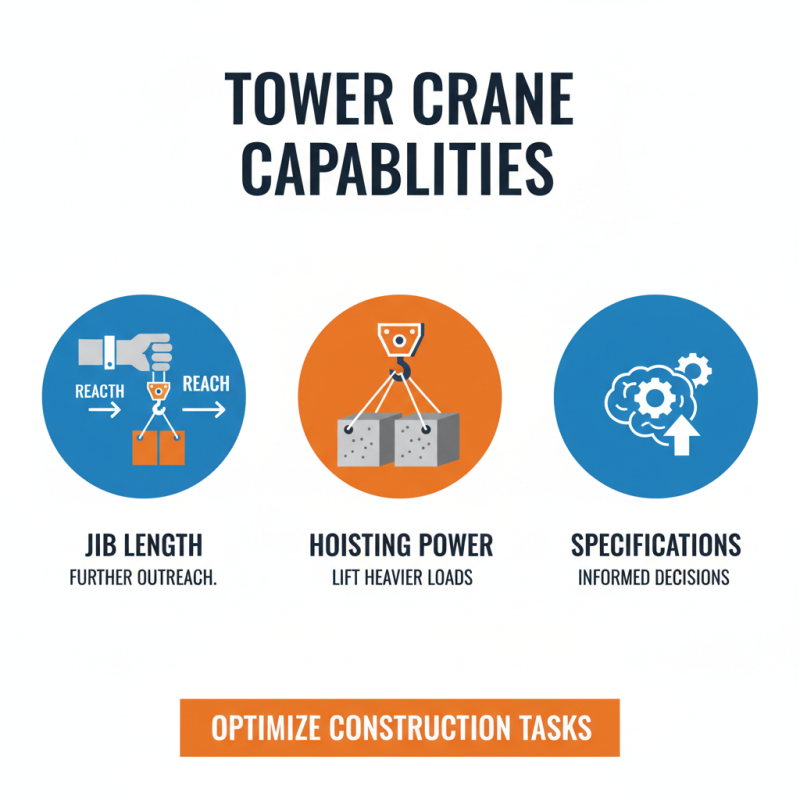

When operating a tower crane, understanding its specifications and features is crucial. Each model has unique capabilities, such as load limits, jib length, and height. A crane with a longer jib can reach further across a construction site. Conversely, a powerful hoisting system can lift heavier materials. Knowing these specifics helps operators make informed decisions on construction tasks.

Proper setup is essential. An incorrect assembly may lead to malfunction or accidents. Pay attention to dimensions; ensure the crane fits the intended work area. Stability is key. Sometimes, issues arise when the ground isn’t level. Regular inspections help identify potential flaws. Operators should be aware of the crane's range. Are you pushing its limits? Overextending can risk safety and efficiency.

Safety features like emergency stops and overload sensors are vital. Yet, these systems only work when properly understood and utilized. Training is fundamental. Consider the crew's knowledge of the crane. Is everyone up to speed? Regular training refreshers can be beneficial. Based on experience, some operators underestimate the need for constant vigilance. This can lead to mistakes. Ensuring everyone is aware of both capabilities and limitations is essential for effective operation.

Operating a tower crane requires a keen understanding of safety procedures. Before beginning any operation, an inspection of the crane is vital. This includes checking the cables, hooks, and overall structural integrity. Any sign of wear or damage must be addressed immediately. Operators should also ensure that all safety devices, like limit switches, are in working order.

Communication is essential on the job site. Operators must establish clear signals with ground crew members. This helps in avoiding accidents during lifts. Everyone involved should be aware of their roles, and constant vigilance is necessary. Sometimes, distractions can lead to errors. It’s crucial to maintain focus and avoid multitasking.

Weather conditions also play a role in safe operation. High winds or rain can affect crane stability. Operators should consistently monitor forecasts and be prepared to halt operations if necessary. Reflecting on past experiences can improve safety awareness. Everyone makes mistakes, but learning from them is part of the process.

Setting up a tower crane requires careful planning and attention to detail. Begin by assessing the site. Ensure the ground is level and stable. Identify any obstacles around the crane's operating range. This is crucial for safety and efficiency.

Check the assembly instructions provided with the crane. Follow them closely. Consider having a skilled technician oversee the setup. Missteps can lead to operational issues later. Engage your team in the process.

Communication is key during assembly.

Tips: Use clear signals to coordinate movements. Double-check connections before lifting any loads. Keep an emergency plan handy.

Position the crane based on your project needs. Make sure it has proper clearance and can reach desired heights. Regularly inspect your crane during operation. Look for signs of wear or malfunction. Small problems can escalate quickly.

Tips: Use a daily checklist for safety inspections. Encourage operators to report any irregularities without hesitation. Safety should always come first.

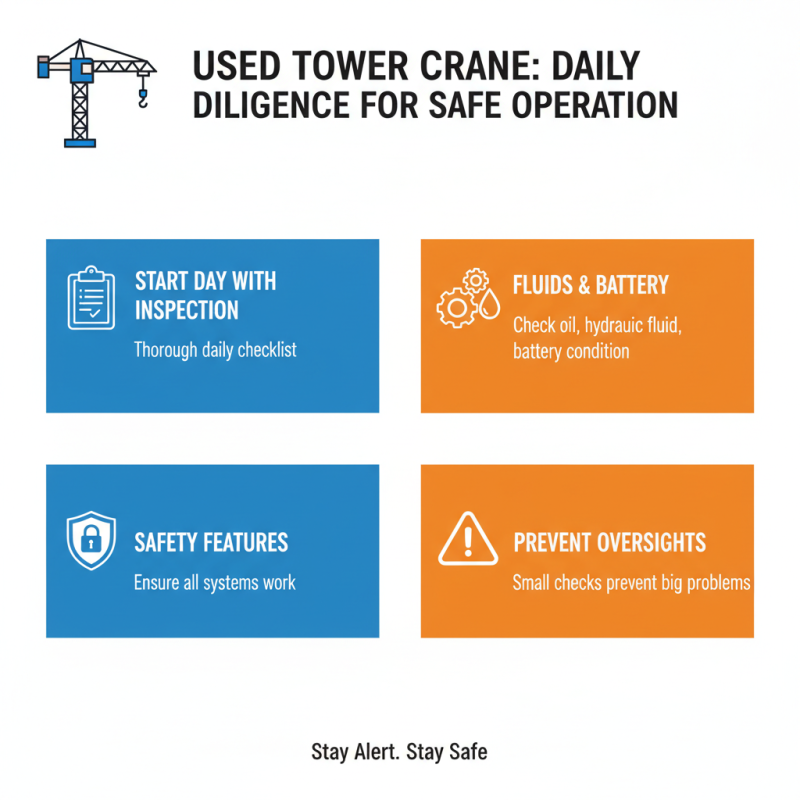

Effective operation of a used tower crane requires diligence in daily checklists and maintenance. Start each day with a thorough inspection. Check the oil levels, hydraulic fluids, and battery condition. Ensure all safety features are functioning well. A small oversight can lead to significant issues later.

**Tip:** Use a checklist. Write down each critical point you need to inspect. This simple tool can save time and prevent mistakes. It helps you stay focused on the details.

Next, pay attention to the cables and pulleys. Look for any signs of wear or fraying. These components bear the load and need to be in good condition. If you notice something off, take action swiftly. Waiting could lead to serious malfunctions.

**Tip:** Keep a maintenance log. Document repairs and observations. This log not only tracks the crane’s health but also helps identify recurring problems. You may find patterns that indicate deeper issues.

Lastly, after your checks, observe how the crane performs throughout the day. Are there unusual sounds? Is the lifting smooth? These small details matter. If something doesn’t feel right, investigate further. Listening to your equipment is as vital as any checklist.

Operating a tower crane effectively requires awareness of common issues that may arise during its use. One frequent problem is excessive sway. This can happen due to wind or unexpected load movements. Operators should closely monitor weather conditions. Sometimes, adjusting the load's position can help stabilize the crane.

Another issue is hoisting problems. This may occur if the load is too heavy or improperly balanced. Operators must ensure the weight does not exceed the crane's capacity. If a load appears stuck, avoid forcing it. Instead, assess the situation calmly. Check for any obstructions before attempting to lift again.

Periodic maintenance is crucial. Neglecting minor issues can lead to major breakdowns. Inspect cables and hooks regularly. Look for signs of wear or damage. Operators should communicate clearly with team members. Miscommunication can lead to accidents. Being proactive about these problems increases safety and efficiency.