The safe and efficient operation of a Tower Crane is crucial in the construction industry. According to a report from the Occupational Safety and Health Administration (OSHA), improper crane operation accounts for nearly 25% of construction-related fatalities. These figures highlight the need for stringent safety measures and effective training programs.

Expert John Smith, a leading authority in crane operations, has emphasized, "The foundation of successful Tower Crane operation lies in proper training and adherence to safety protocols." His insight underscores the importance of understanding the complexities involved in operating Tower Cranes, which include load capacities, site conditions, and weather impacts.

Challenges exist, however. Many operators overlook routine inspections and fail to assess their surroundings adequately before lifting. Such oversights can lead to dangerous incidents and costly delays. As the industry evolves, it is imperative that operators continuously refine their skills and embrace best practices for Tower Crane safety and efficiency.

When choosing a tower crane, it is essential to understand the types available. The most common types include hammerhead, luffing jib, and flat-top cranes. Each type serves unique purposes based on the project's needs. Hammerhead cranes are versatile. They are typically used on larger jobs. Their design allows for considerable lifting capacity and height.

Luffing jib cranes excel in tight spaces. They can swing their jibs to avoid obstacles. This makes them ideal for urban construction sites. Flat-top cranes are simpler in design, offering an open work area. They are often used in projects requiring multiple cranes operating simultaneously. It’s important to choose based on specific project requirements.

However, operating a crane efficiently can be challenging. Operators need extensive training and experience. Miscommunication among team members often leads to errors. Regular maintenance is also crucial. It helps prevent breakdowns that could halt work. Each crane has its operational quirks. Understanding these can lead to better performance and safety.

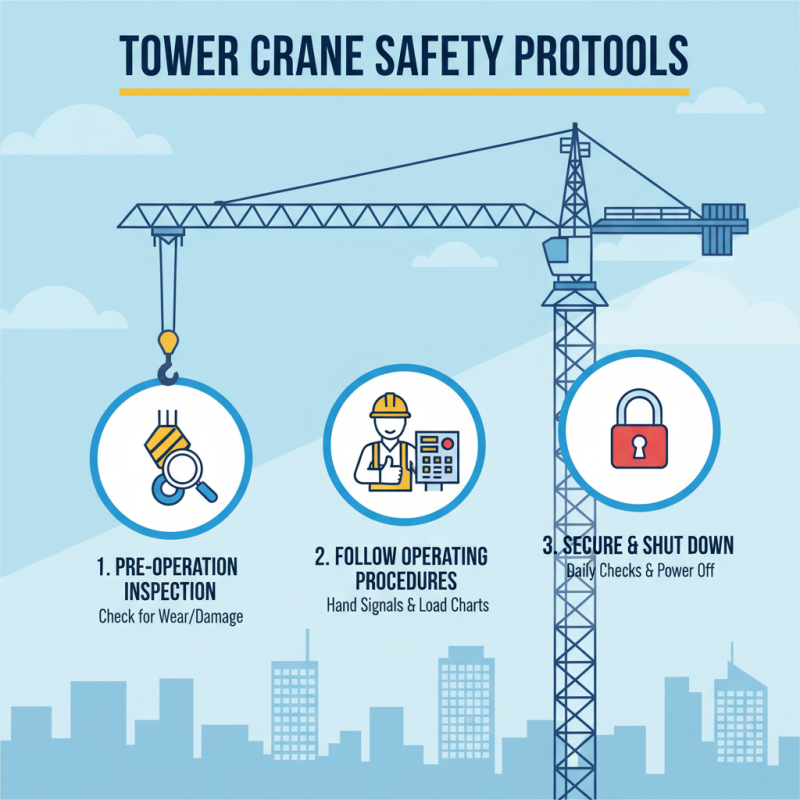

Operating a tower crane requires strict adherence to safety protocols. These protocols ensure the safety of operators and those working nearby. Before starting, it's crucial to conduct a thorough inspection of the crane. Look for signs of wear or damage. This simple step can prevent accidents.

Always communicate clearly with your crew. Use hand signals or radios for effective communication. Misunderstandings can lead to costly mistakes. Operators should keep an eye on the load and the surrounding area at all times. Distractions can be dangerous.

**Tips:** Always be aware of the weather. Wind can significantly affect crane stability. If strong winds are present, pause operations. Training is vital. Ensure all crew members understand safety procedures. Regular drills can reinforce these practices. Safety gear should be worn at all times.

Reflect on past incidents to improve safety measures. Each experience offers learning opportunities. Continuous improvement is essential for a safe working environment. Following these protocols can help in operating tower cranes effectively.

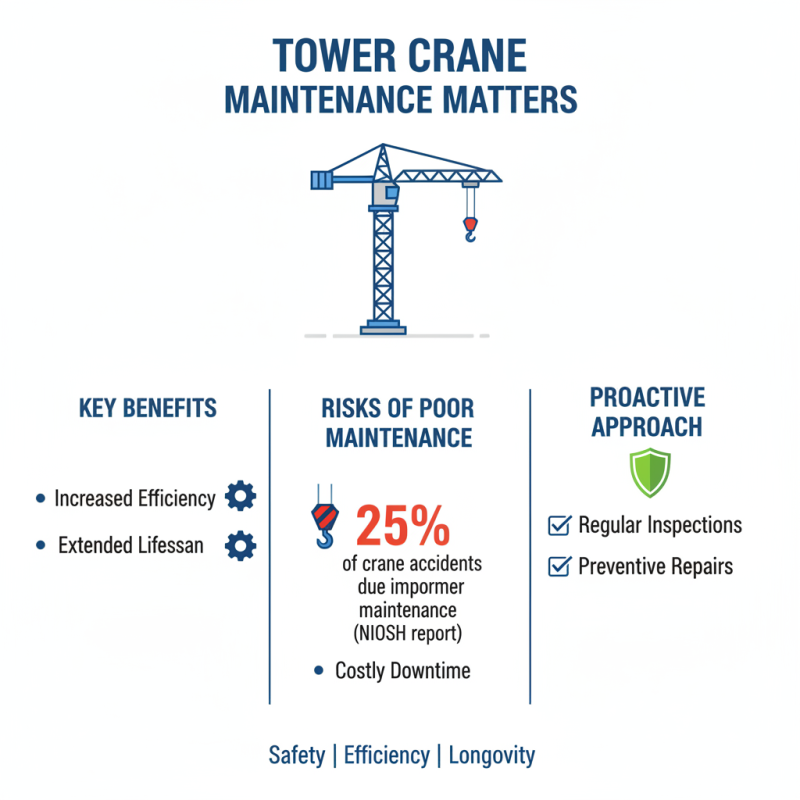

Regular maintenance is crucial for tower crane efficiency and longevity. According to a report by the National Institute for Occupational Safety and Health, improper maintenance can lead to 25% of crane-related accidents. A proactive approach can prevent costly downtime and extend the crane's operational life.

Daily inspections should include checking the ropes, pulleys, and attachment points. This can prevent unexpected failures during operation. Documentation of maintenance activities is also essential. Around 15% of crane failures are due to maintenance lapses, highlighting the need for diligent tracking. Operators should consider using a digital log to streamline this process.

Moreover, performing periodic load testing is vital. Industry standards suggest this should occur at least every six months. Testing ensures the crane can safely manage its rated capacity. Neglecting these tests can lead to disastrous results. The importance of practical training for operators cannot be overstated, as human error contributes to nearly 70% of crane incidents. Regularly revisiting training materials can enhance awareness and safety practices in the field.

When it comes to operating tower cranes, safety starts with proper training. According to the National Commission for the Certification of Crane Operators (NCCCO), crane operators must complete a specialized training program. This includes both classroom instruction and hands-on experience. Successful completion leads to certification, which is essential and legally required in many regions.

Tips: Always check your training provider’s credentials. Not all training programs are created equal.

Certification standards emphasize knowledge of rigging, load calculations, and safety regulations. The Occupational Safety and Health Administration (OSHA) mandates that operators renew their certifications every three years. This ensures they stay updated on industry practices. Regular training refreshers can help prevent accidents caused by outdated knowledge.

Tips: Schedule regular training updates to maintain compliance and safety awareness.

Many operators neglect the importance of continuous learning. It’s easy to fall into a routine but staying informed about new safety regulations is crucial. Statistics show that cranes involved in accidents often have operators lacking recent training. Being proactive can significantly reduce risk on the job site.

When operating a tower crane, understanding load capacity is essential. Each crane has specific specifications that dictate how much weight it can safely lift. Operators must analyze these figures closely. Site conditions also play a significant role. Wind speed, ground stability, and overhead obstructions can impact lifting potential. It is crucial to assess these factors daily.

Many operators overlook site conditions. They may rely too heavily on crane specifications alone. However, a safe lift requires a balance. For instance, a perfectly calibrated crane cannot compensate for high winds. An unexpected gust can shift loads, leading to accidents. Regular site evaluations should not be neglected.

Load capacity limits often require adjustments. Even minor changes in the environment can necessitate a new plan. Operators should not become complacent. They must be prepared to adapt constantly. This flexibility can significantly enhance safety and efficiency while operating a tower crane.