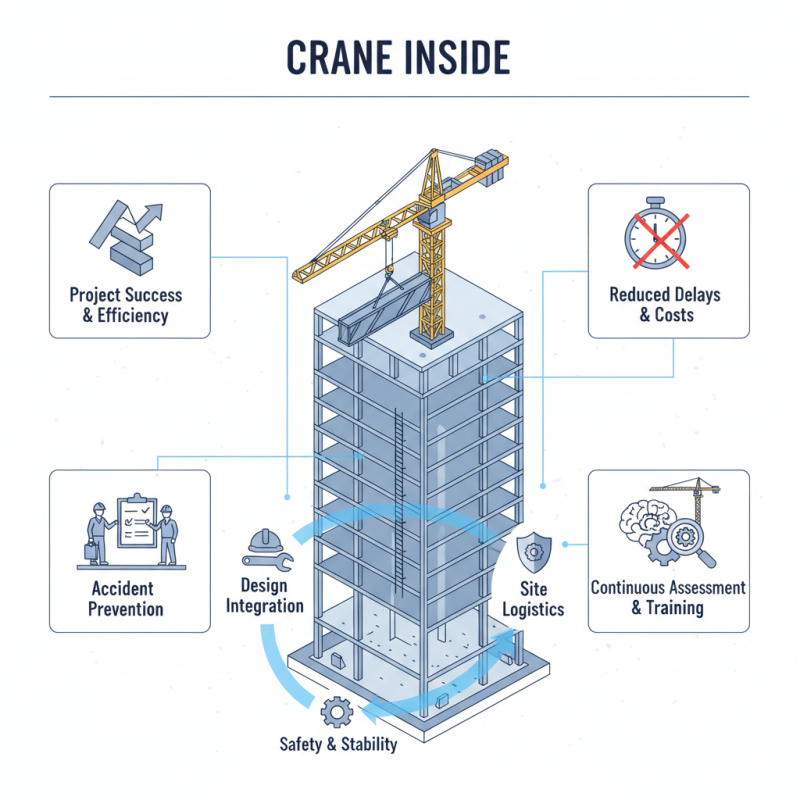

In structural engineering, the role of "Crane Inside" is often underestimated. Industry expert John Davis states, “The effectiveness of crane operations directly influences project success.” This highlights the significance of integrating cranes into design processes.

Cranes are essential for lifting heavy materials at construction sites. The placement of cranes can affect site logistics. Misjudgments can lead to delays and increased costs. Therefore, careful planning is vital.

Moreover, the stability and safety of structures can hinge on how cranes are utilized. Poor crane positioning might lead to accidents or structural issues. This potential danger reflects a need for more training in crane operations. It is crucial for engineers to assess the role of cranes continually. To ensure safety and efficiency, we must prioritize the role of "Crane Inside.

Crane Inside plays a crucial role in structural engineering. These cranes are essential for lifting heavy materials safely. They enable construction teams to move large components to elevated areas. This efficiency is vital in skyscraper and bridge construction. Without cranes, these projects would face significant delays and increased risks.

Proper crane placement is key. A poorly positioned crane can lead to safety hazards. Workers must always consider weight limits and swing radius. Coordination is critical when cranes lift and position heavy loads. Miscommunication can result in accidents, potentially causing injury. Engineers often need to rethink crane logistics for complex sites.

Visibility and access are challenges. Some construction areas have limited space. Cranes must operate in confined environments, making planning essential. Engineers often use simulations to visualize crane movements. This helps spot potential issues early. However, these plans require constant updates and adjustments on site. Continuous reflection on crane operations improves efficiency and safety.

Cranes play a vital role in construction processes. They help lift heavy materials that are otherwise difficult to handle. From steel beams to large concrete slabs, cranes make these tasks easier. Their ability to reach high and move loads horizontally is unmatched. This results in greater efficiency on job sites.

When using cranes, safety should always be a priority. Operators need proper training and experience. Ensure the crane is regularly maintained. Inspect cables and pulleys before use. Always follow guidelines to prevent accidents. Poor communication can lead to mistakes. Clear signals and teamwork are essential.

Remember to consider the placement of cranes. They need to be positioned correctly to maximize their reach. In tight spaces, this can be a real challenge. Often, site managers must adjust plans. It’s crucial to evaluate the site conditions continuously. This flexibility can save time and resources. Not every job goes as planned, and that's okay. Adjusting dynamically is part of the process.

Crane usage in structural engineering is crucial yet comes with inherent safety risks. Working with cranes involves lifting heavy materials, often at great heights. If proper safety protocols are not followed, accidents can occur, leading to injuries or fatalities. For instance, a sudden equipment failure can cause loads to drop unexpectedly. This demands stringent checks and regular maintenance of cranes.

Training workers is essential. Operators need specialized skills to handle complex tasks safely. Regular safety drills can help prepare teams for emergencies. However, even well-trained teams may face unexpected challenges. Weather conditions, such as high winds, can impact crane stability. It’s a stark reminder that even with preparation, conditions can shift suddenly.

Load management also plays a pivotal role. Miscalculating weight limits can lead to catastrophic failures. Monitoring loads closely is vital. Moreover, the placement of cranes should be carefully considered. Surrounding structures and pedestrian areas must be assessed. These logistical concerns often reveal overlooked details that could jeopardize safety. It's essential to continuously reflect on these aspects during the project's lifecycle.

| Aspect | Importance | Safety Measures |

|---|---|---|

| Load Capacity | Ensures structural integrity and prevents overloading. | Regular inspections and compliance with weight limits. |

| Stability | Critical for preventing tipping and accidents during operations. | Proper placement and stabilization techniques used. |

| Operator Training | Essential for safe and effective crane operation. | Mandatory certification and ongoing training sessions. |

| Environmental Factors | Affects crane performance and safety during operations. | Monitoring weather conditions and site assessments. |

| Maintenance | Prevents mechanical failure and enhances safety. | Scheduled maintenance and detailed upkeep logs. |

Crane operations play a crucial role in structural engineering. They lift heavy materials, shaping the backbone of construction projects. The correct use of cranes ensures that these materials reach the right heights and locations. However, improper crane maneuvers can lead to structural integrity issues. For example, unexpected swings of a load might cause distress to beams or columns.

Monitoring crane operations is vital. Engineers should assess the load limits carefully. Even a small miscalculation can lead to disasters. It's essential to train operators thoroughly. A lack of experience can result in improper handling of loads. Knowing the precise weight and center of gravity is just as important. If not, the entire structure could be at risk.

Furthermore, maintenance of cranes cannot be overlooked. Regular checks for wear and tear are necessary. Hydraulic systems must be functioning properly. Gears and cables need attention. Neglecting these aspects can jeopardize entire projects.

Reflecting on crane usage is a continuous process. A mishap can lead to costly delays and safety hazards.

Crane technology is evolving rapidly, shaping the future of structural engineering. Advanced sensors and automation are being integrated into cranes. This development ensures precision in heavy lifting tasks. It's not just about efficiency; safety is also on the rise.

Remote operation is becoming common. Operators can control cranes from a distance, minimizing risks. Moreover, smart cranes can communicate with each other. This feature helps in coordinating complex lifts on construction sites. However, as we embrace these innovations, we need to consider their potential drawbacks.

The reliance on technology can create vulnerabilities. If systems fail, the consequences could be severe. Training remains essential. Engineers must understand both the machinery and potential failures. Balancing automation with human insight is crucial for navigating this evolving landscape in structural engineering.