Construction cranes play a crucial role in modern building projects. These towering machines are essential for lifting heavy materials. From steel beams to concrete blocks, they move loads that human workers cannot.

A construction crane operates using a complex system of pulleys and cables. This intricate design allows it to reach great heights and distances. Within a busy construction site, cranes can be seen rotating and lifting, creating a rhythm of productivity. However, their operation requires careful planning and skilled operators to prevent accidents.

Despite their efficiency, cranes can pose risks. A miscalculation can lead to disaster. Workers must be vigilant, monitoring load weights and ensuring stability. Ultimately, the role of construction cranes in the industry is indispensable, yet it requires constant awareness and improvement to enhance safety and reliability.

A construction crane is a vital piece of equipment on building sites. It assists in lifting and moving heavy materials. Cranes come in various types, each designed for specific tasks. Some cranes are mobile, while others are stationary. Their ability to reach great heights is crucial in construction.

The primary purpose of a crane is to improve efficiency. Workers can lift materials that would otherwise require many people. This saves time and reduces labor costs. Cranes help transport beams, concrete blocks, and other heavy loads safely. They are equipped with pulleys, cables, and hooks to perform these tasks.

However, cranes also present challenges. Operators must be skilled to ensure safety. Mistakes can lead to accidents or injuries. Rigging a load incorrectly can be risky. Each lift requires careful planning. Construction sites are dynamic and can change quickly. Operators must adapt to various conditions. This makes crane operation both innovative and complex.

Construction cranes are essential in modern building projects. They come in various types, each serving specific functions. Tower cranes are often seen on skyscrapers. They provide height and stability. These cranes can lift heavy materials to great heights, making them ideal for tall structures.

Another type is the mobile crane. It's versatile and can move around the construction site easily. This flexibility allows quick repositioning for different tasks. However, using mobile cranes requires careful planning. They may not reach the same heights as tower cranes but can navigate tight spaces well.

Lastly, there are crawler cranes. They have tracks instead of wheels, providing stability on uneven ground. These cranes are excellent for job sites with challenging terrains. Still, they require a lot of setup and take time to get into position. Cranes are amazing but can be complex. Misjudgments can lead to setbacks, highlighting the importance of skilled operators.

| Crane Type | Description | Load Capacity | Common Applications |

|---|---|---|---|

| Tower Crane | A fixed crane typically used in the construction of tall buildings. | 20 tons to 100 tons | High-rise buildings, bridges |

| Mobile Crane | A versatile crane that can be moved around, usually mounted on wheels or tracks. | 10 tons to 500 tons | Construction sites, road work, heavy lifting tasks |

| Luffing Jib Crane | A crane with a movable jib that can be luffed (raised or lowered) to change the radius. | 10 tons to 50 tons | Confined spaces, urban construction |

| Crawler Crane | A crane that moves on tracks instead of wheels, providing better stability on soft ground. | 50 tons to over 1,000 tons | Heavy construction, mining |

| Overhead Crane | A type of crane that runs on rails along the ceiling of a factory or warehouse. | Up to 100 tons | Manufacturing, warehouse operations |

Construction cranes are vital to modern building projects, facilitating the lifting of heavy materials. Their operation relies on complex mechanisms that coordinate various parts to work together efficiently.

Cranes typically use a system of pulleys, winches, and cables. These components enable the crane to lift and lower objects with precision. A key metric in crane operations is the load capacity, which can range from 10 tons to over 1,000 tons. According to industry reports, cranes can dramatically cut down on labor time. For instance, job sites report up to 40% faster completion rates when cranes are utilized.

Tips: Regular maintenance is essential. Inspect cables and pulleys frequently to avoid failures. Always check load limits before lifting.

The mechanics of cranes also involve hydraulics in many cases. These systems convert pressure into movement, making lifting easier. Unfortunately, mistakes can lead to accidents. Misjudging the load can cause equipment failure. Some operators overlook safety protocols, leading to increased risk.

Tips: Always practice proper safety procedures. Make sure everyone on the site understands the crane's operation. Stay aware of the surroundings while operating.

Construction cranes are powerful machines, but their operation comes with important safety standards. These regulations help ensure the safety of workers and the public. They cover everything from crane design to operator training. Each construction site must follow local and national codes.

Crane operators must undergo thorough training. This training ensures they understand the equipment and safety protocols. Proper inspection of the crane is vital before use. Operators are responsible for checking slings, hooks, and load limits. They must remain vigilant during operations, as conditions can change rapidly.

Despite strict regulations, accidents can still happen. Human error or equipment failure can lead to serious consequences. Regular training updates and rigorous inspections are crucial, but they are not foolproof. The challenge lies in maintaining a culture of safety on construction sites. Every worker must prioritize precaution and communication to minimize risks.

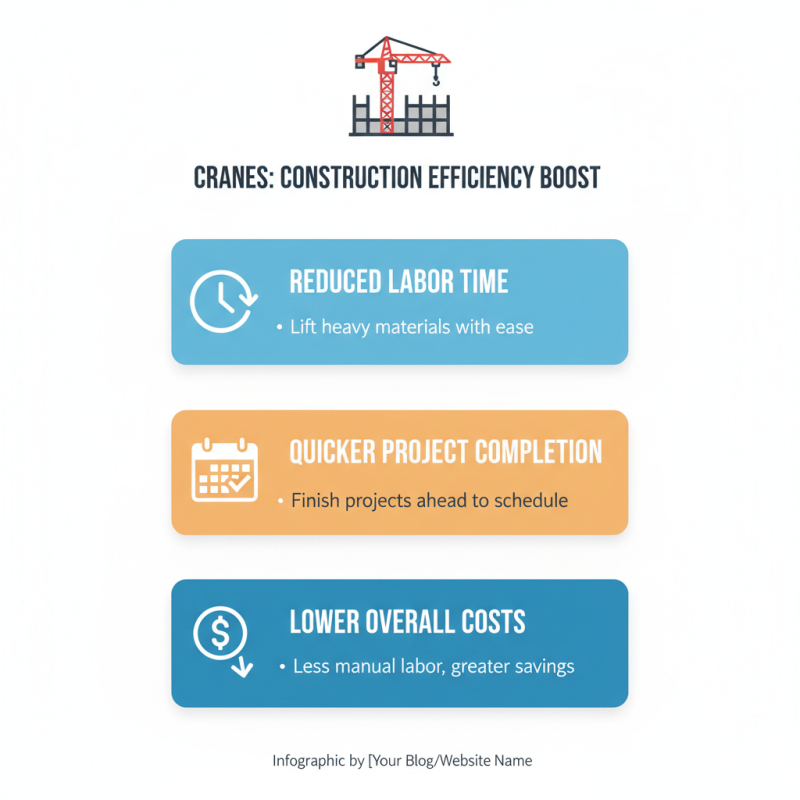

Cranes play a vital role in construction. They enhance efficiency in lifting heavy materials with ease. According to industry statistics, cranes can reduce labor time significantly. This translates to quicker project completion and lower overall costs. In many cases, cranes can handle loads that would take multiple workers hours to lift.

However, cranes also come with challenges. The setup and operation require skilled operators. Safety remains a primary concern. Even with advanced training, accidents can happen. A small mistake can lead to serious injuries or damage. This constant need for caution can slow down operations at times.

Data shows that construction sites with cranes improve productivity by over 30%. This stark increase highlights their importance. Yet, not everyone recognizes their benefits. Some still underestimate how cranes transform project timelines. Understanding this impact can reshape future planning and resource allocation in construction projects.