When considering construction equipment, the Dahan Used Tower Crane stands out. This crane combines efficiency and versatility. Many contractors seek durable and reliable tower cranes for various projects. A Dahan Used Tower Crane often offers excellent performance at a lower cost. However, buying used equipment requires caution.

Inspecting the crane’s condition is crucial. Look for signs of wear and tear. Ask about maintenance records. You want a crane that has a good history. Some buyers rush into purchases, and this can lead to regrets. Proper research is key.

In this guide, we will review the best Dahan Used Tower Cranes available in 2026. We will provide insights on features, specifications, and customer feedback. This information will help you make an informed decision for your next project. Stay tuned for valuable tips and suggestions to ensure you choose wisely.

In the construction industry, used tower cranes are gaining attention. They balance cost efficiency and operational excellence. A recent report showed that around 60% of companies prefer used cranes to save costs without compromising quality. Dahan used tower cranes come equipped with key features that support various project demands.

For instance, many models offer adjustable heights and load capacities. This adaptability allows them to function in diverse environments. Their compact designs often ease transportation and setup, crucial for tight job sites. However, not every used crane meets the same standards. Some may show signs of wear that could lead to operational inefficiencies or safety risks.

Furthermore, maintenance history plays a vital role. A 2022 survey indicated that about 30% of buyers faced unexpected repair costs shortly after purchase. Investing in thorough inspections before acquiring a used crane is essential. Pay attention to wear on critical components and ensure proper certifications are in place. Choosing the right model requires careful consideration and a deep understanding of these factors.

In 2026, choosing the right Dahan tower crane is essential for construction projects. Different types cater to varied lifting capacities and project requirements. There are standard models, luffing cranes, and self-erecting cranes. Each type serves distinct purposes. For example, luffing cranes excel in tight spaces. They offer flexibility, especially in urban areas.

Reports indicate that the global tower crane market is expected to grow by 5.5% annually. This growth reflects an increased demand for efficient lifting equipment. Compact models gain traction among small construction firms. They help save on operational costs while maximizing productivity.

Features vary across models. Load capacities might range from 2 to 60 tons. The choice often leads to reflection on long-term investment vs. short-term needs. Proper understanding of these types aids in making informed decisions. Yet, not analyzing all factors can lead to costly mistakes. Each project has unique requirements that impact crane selection.

When considering a used tower crane, several factors come into play.

The crane’s age and condition are paramount. Inspect for wear and tear.

Check the cables and hoist mechanisms. An older crane may seem cheap but could require costly repairs.

Don’t underestimate inspection time; it ensures safety and reliability.

Tip: Look for any rust or signs of poor maintenance.

Ask for maintenance records. A well-maintained crane often indicates a responsible previous owner.

Another aspect is the lifting capacity.

Determine your project’s needs first. A crane that is too weak can derail your work schedule.

Conversely, an over-capacity crane can lead to unnecessary expenses.

Tip: Calculate your load requirements based on project specifications.

This helps avoid misjudgments and financial pitfalls.

Ultimately, consider the logistics of transporting the crane.

Check if the crane fits in your workspace.

Transport costs can be significant, so research local regulations and procedures.

Every choice should make sense for your specific needs.

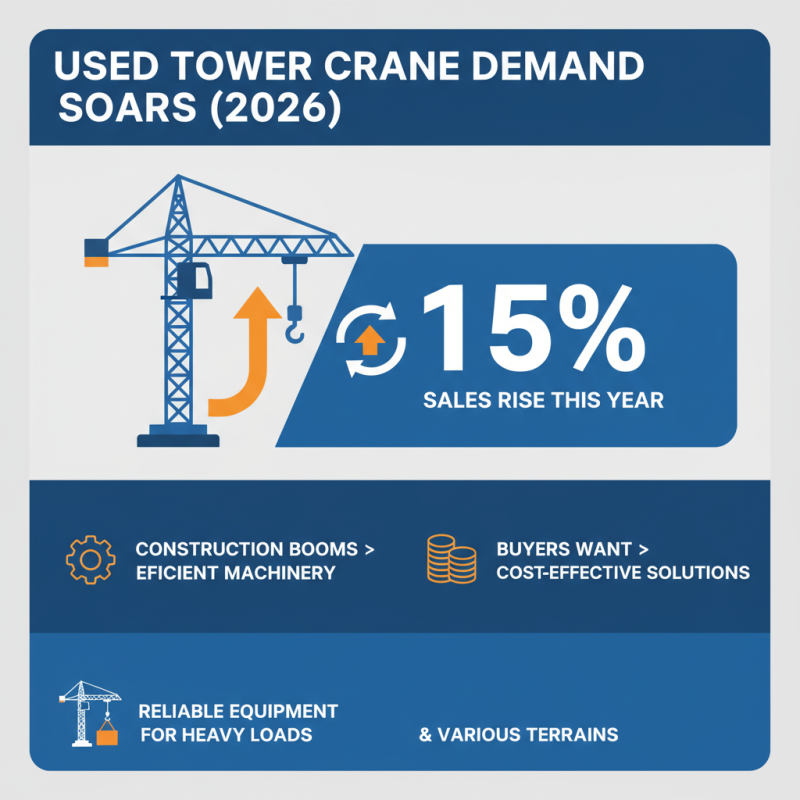

The demand for used tower cranes is increasing in 2026. As construction projects grow, efficient machinery is essential. Market trends indicate that buyers prefer cost-effective solutions. Data shows a 15% rise in sales for used cranes this year alone. Crane operators seek reliable equipment that can handle heavy loads in various terrains.

When considering a used tower crane, pay attention to maintenance history. Machines that have been regularly serviced often perform better. Look for signs of wear, including rust or damaged parts. These issues could indicate deeper problems. Always ask for inspection reports to verify the crane's condition.

Tip: Ensure you check load charts before making a decision. Understanding the crane's capabilities will help you avoid costly mistakes. Additionally, consider its operational limits; this can affect project timelines. A well-chosen crane can save time and increase safety.

Maintaining a used tower crane is crucial for its longevity and reliable operation. Regular inspections should be part of your routine. Check for any signs of wear and tear. This includes cables, pulleys, and hydraulic systems. A small issue can quickly lead to expensive repairs. Pay close attention to fluid levels and mechanical parts, as neglect can cause significant failures.

Lubrication is essential. Properly lubricated components help reduce friction and wear. Make sure to follow the manufacturer’s recommendations for lubricants and intervals. In addition, cleaning the crane regularly is vital. Dirt and grime can cause parts to malfunction. Set a schedule to inspect and clean each area of the crane thoroughly.

It's also essential to train operators effectively. They must understand the crane's limitations. Even experienced operators can make mistakes. Regular training sessions can help keep safety protocols fresh in their minds. Document every inspection and maintenance activity for future reference. Mistakes might happen, but learning from them can lead to improvements in your maintenance strategy.