In the world of construction, choosing the right equipment is crucial. Construction cranes play a vital role in lifting heavy materials and ensuring project success. Bill Anderson, a leading expert in the construction industry, states, "Selecting the right crane can define a project's efficiency." His insight emphasizes the need for careful planning.

In 2026, various construction crane models will be available. Each model has unique features suited for different projects. From compact cranes for urban sites to larger cranes for extensive construction, options abound. Many builders struggle to choose the best fit. The wrong choice can lead to project delays and increased costs, reflecting the importance of informed decisions.

Construction cranes are not just machines; they are essential tools. They can raise efficiency but also pose risks without proper knowledge. Make sure to consider the project type, site conditions, and load requirements before making a decision. The right crane enhances performance, but the wrong one can create setbacks. Therefore, ongoing evaluation and adaptation will always be necessary.

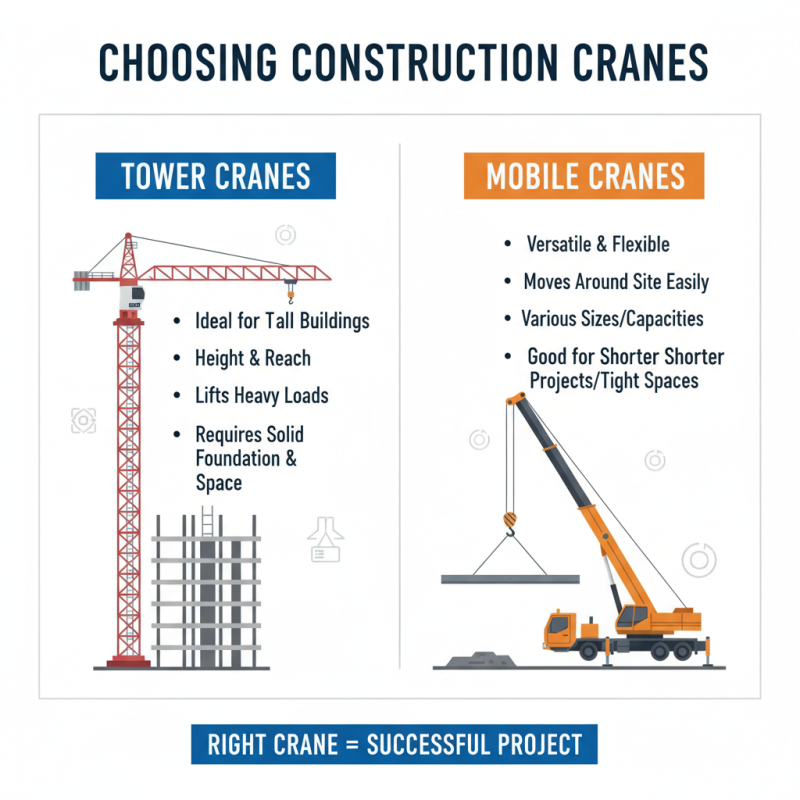

When planning a construction project, choosing the right crane is crucial. Different models serve different purposes. Tower cranes are ideal for tall buildings, providing height and reach. They can handle heavy loads, making them popular in skyscraper construction. However, they require a solid foundation and space.

Mobile cranes offer flexibility and can move around the site. Their versatility is a double-edged sword; while they can access tight spots, they may lack the lifting capacity of fixed cranes. A careful evaluation of the site can help determine the best fit.

Rough terrain cranes are also a notable choice. They are designed for off-road conditions. However, their speed is lower. Challenges arise when navigating uneven surfaces, highlighting the need for skilled operators. The right crane makes a difference, but improper choices can lead to inefficiencies.

In modern construction, mobile cranes play a pivotal role.

They offer unmatched versatility and efficiency, essential for any project. According to industry reports, these cranes can improve productivity by up to 30% on-site. Their ability to maneuver in tight spaces makes them ideal for urban construction projects.

When it comes to high-rise construction, tower cranes play a pivotal role. These machines are engineered to lift heavy loads efficiently. Their design allows for maximum stability and reach, essential for tall structures. Operators must manage various performance metrics. These include lifting capacity, height, and speed. Understanding these factors can lead to better project outcomes.

Capacity is crucial for tower cranes. Each crane has a specific lifting limit. It's essential to match the crane's capacity to project needs. Sometimes, this is overlooked, leading to complications. Operators may underestimate weight demands. This often results in delays or equipment failure. Height is another vital metric. A crane must reach the building's top safely.

It's not just about the numbers. Proper setup and location also matter. Cranes should be positioned to minimize the swing of loads. This reduces risks during operation. Communication among teams is key. Miscommunication can lead to accidents. Continuous evaluation of performance metrics allows for adjustments. Project managers and operators must be proactive. Reflecting on past experiences leads to improved safety and efficiency.

| Model | Max Load Capacity (tonnes) | Height Reach (meters) | Working Radius (meters) | Ideal Applications |

|---|---|---|---|---|

| Model A | 10 | 50 | 30 | Residential Buildings |

| Model B | 15 | 70 | 35 | Commercial Projects |

| Model C | 8 | 45 | 25 | Industrial Sites |

| Model D | 20 | 90 | 40 | High-Rise Structures |

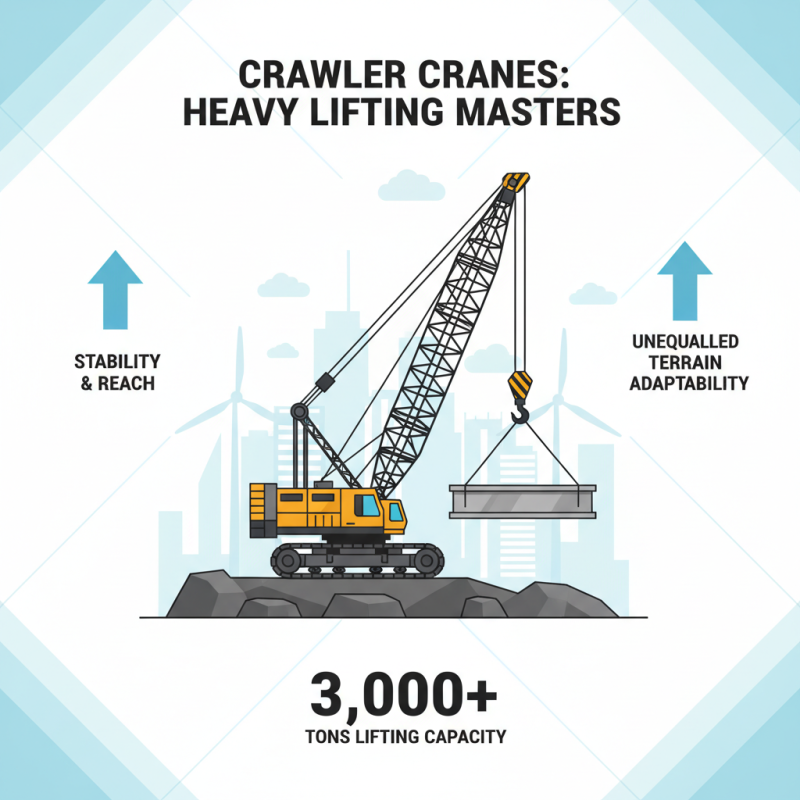

Crawler cranes are essential for heavy lifting in challenging environments. They excel in stability and reach, making them ideal for construction sites with uneven terrain. According to industry reports, crawler cranes can lift loads exceeding 3,000 tons. This capacity allows them to handle massive equipment or building materials with ease.

These cranes operate on tracks instead of wheels. This design enhances balance, especially in soft or unstable ground. The ability to maneuver through rough environments is critical. However, operators need to be cautious. Misjudgments can lead to tipping or sinking. It's crucial to assess ground conditions thoroughly before deployment.

Moreover, the setup of crawler cranes can be time-consuming. Each project may require a unique configuration based on load type and location. Training operators is vital to maximize safety and efficiency. Continuous advancements in technology are helping improve these cranes. However, challenges remain in adapting to diverse job sites. Understanding these challenges can lead to better planning and execution.

Selecting the right crane model is crucial for any construction project. Various factors influence the success rate, including load capacity, reach, and site conditions. Industry reports indicate that projects with properly chosen equipment have a 30% higher success rate. Understanding these factors can drastically reduce delays and budget overruns.

The terrain plays a significant role in crane selection. A study revealed that over 40% of projects face delays due to inadequate equipment for specific site conditions. For instance, rough terrain may require all-terrain cranes, while tight urban environments might necessitate compact models. Ensuring the model fits the environment can mitigate logistical issues.

Load capacity also cannot be overlooked. Many projects encounter challenges because the crane cannot handle the weight. Over 25% of crane-related accidents stem from miscalculating this pivotal aspect. Therefore, a thorough analysis of weights and balance is vital. A mistake in this area can lead to safety risks, financial losses, and schedule disruptions.